SHOP

CAPABILITIES

SHOP

CAPABILITIES

SHOP

CAPABILITIES

Quality Service & Competitive Pricing

Our comprehensive, state of the art manufacturing facility specializes in the fabrication of steel products. We are equipped to produce a broad range of products, from simple detail parts up to complex multi-level assemblies.

We thrive using the simple philosophy of competitive pricing, excellent lead times, professional workmanship and outstanding customer service.

As a major consumer of steel, Valley Fab Corp stocks a large amount of steel and is ready to meet any demand.

We offer full fabrication, machining, and manufacturing capabilities to meet your specific needs. Below are some of our core capabilities, but we are willing to take on other value-added projects as required to support our customers. Please contact us with any questions regarding our capabilities.

Certifications

Valley Fab Corp. is ISO 9001:2015 registered.

The scope of this Quality Management System Governs:

Contract Manufacturing includes Plasma, Laser cutting, Forming, Fabrication, Fiberglass, Painting, and Machining for Structural Steel and Cellular Divisions.

Machines

• Peddinghaus CNC Beamline

• Amada Table Laser Machine

• Titan Burn Table

• Messer Burn Table (x2)

• Ocean Avenger Beam Line

• Hydemich M-16A Saw

• Hydem V20 Saw

• VT100HML-60-Cts-Saw

• Spartans Iron Worker

• GRD50 Flex Drill Machine

• Acer Drill Brake

• Accurl Press Brake

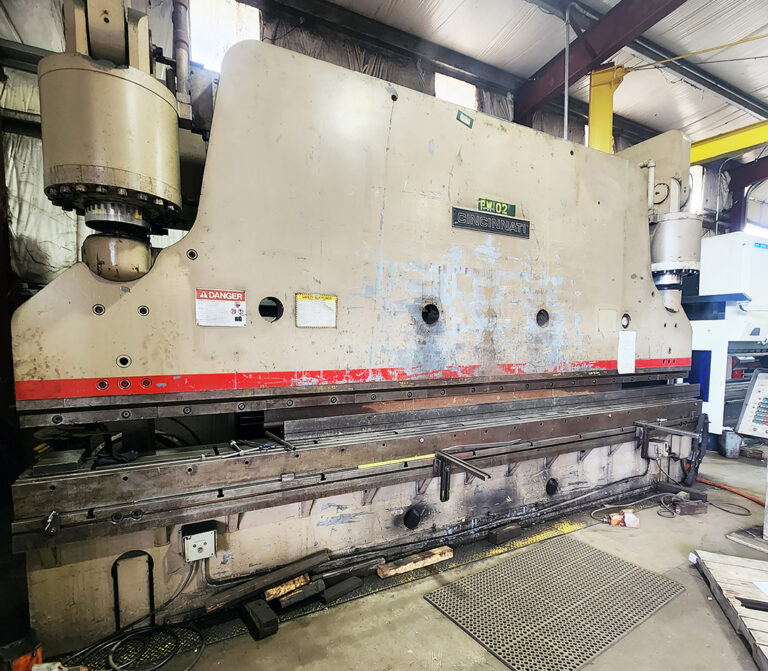

• Cincinnati Press Brake

• Truck Punch Presses (x3)

• CNC Beamline

• Mazak Machine

• Haas VF1 Machine

• Haas TL3 Machine

• Metaform Roll Former

• Accurl Shear

• Whitney Press Brake

Capabilities

Laser Capabilities

Sheet Capacity – 5’ x 10’

• Mild Steel Cutting up to .750″ Thick

• Stainless Steel Cutting up to .500″ Thick

• Aluminum Cutting up to .250″ Thick

Plasma and Torch Cutting:

Sheet Capacity – 8’ x 40’

High-definition Plasma cutting capabilities up 2″ thick with contour beveling and true hole features.

Torch Cutting up to 6” thick.

Brake Forming

Capacities ranging from 100 tons to 750 tons, are designed to efficiently form steel parts up to 20 feet in width.

Our additional capabilities include:

• 3/4” A572-50: 8 feet to 60 feet

• 7/8” A572-50: 6 feet to 30 feet

• 1” A572-50: 5 feet to 20 feet

For larger-scale projects, we leverage our strong partnerships with external vendors, which allow us to handle oversized requirements.

Welding

Our welding team consists of certified professionals trained to AWS D1.1 standards, ensuring the highest level of quality and consistency in every weld. We specialize in a variety of welding techniques, including MIG, TIG, and stick welding, allowing us to meet diverse project requirements.

Robotic Welding:

We have eight axis robotic welding capabilities; it gives flexibility to meet your volume needs, efficiency and consistency.

Shearing:

Mild steel and aluminum up to .250″ thick and 10 feet in width.

Metal Finishing:

- Sanding/Grinding:

Smooths surfaces to prepare for further finishing. - Tumbling:

Removes rough edges and improves surface quality. - Metal Graining/Polishing:

Creates a visually appealing finish. - Painting:

Provides protective coatings in a variety of colors and finishes to suit customer specifications. - In addition, we have established partnerships with reliable external vendors to support specialized finishes such as Galvanizing and Media Blasting. This collaborative approach ensures that we can meet a wide range of finishing requirements, tailored to your project needs.

Drilling:

Drilling line is capable of drilling up 40” in height and 40’ in length – Beam, Channel, Angel, Tube and Flat Bar

We provide a comprehensive range of metal finishing services designed to enhance the appearance and durability of your products. Our offerings include:

Machining:

We have various capabilities to produce complex parts and work with a range of materials. Our CNC machines can perform highly complex machining functions such as drilling, threading, tapping, milling, turning, slotting, chamfering, beveling, boring and much more. In addition we have a variety of manual machines for less complex operations or machining job.

Quality Service & Competitive Pricing

Our comprehensive, state of the art manufacturing facility specializes in the fabrication of steel products. We are equipped to produce a broad range of products, from simple detail parts up to complex multi-level assemblies.

We thrive using the simple philosophy of competitive pricing, excellent lead times, professional workmanship and outstanding customer service.

As a major consumer of steel, Valley Fab Corp stocks a large amount of steel and is ready to meet any demand.

We offer full fabrication, machining, and manufacturing capabilities to meet your specific needs. Below are some of our core capabilities, but we are willing to take on other value-added projects as required to support our customers. Please contact us with any questions regarding our capabilities.

Machines

• Amada Table Laser Machine

• Titan Burn Table

• Messer Burn Table

• Ocean Avenger Beam Line

• Hydemich M-16A Saw

• Hydem V20 Saw

• VT100HML-60-Cts-Saw

• Spartans Iron Worker

• GRD50 Flex Drill Machine

• Acer Drill Brake

• Accurl Press Brake

• Cincinnati Press Brake

• Truck Punch Presses (X3)

• CNC Beamline

• Mazak Machine

• Haas VF1 Machine

• Haas TL3 Machine

• Metaform Roll Former

• Accurl Shear

• Whitney Press Brake

Machine Capabilities

Laser & Plasma:

Our lasers range in power up to 4000 watts with the capability of cutting mild steel up to .750″ thick, stainless steel up to .500″ and aluminum up to .250″. We have high-definition Plasma capabilities that can process up 2″ thick in addition to torch-cutting.

Press Brake

Our press brake range from 100 to 750 tons and is capable of forming steel parts up to 16 feet wide. We have a wide variety of flexible tooling to accommodate most part configurations.

Welding

At Valley Fab Corp we distinguish ourselves by providing the best welding services available. Our welding department staffs certified welders to AWS D1.1 to ensure consistent quality and reliable welds. In addition, we have robotic welding capabilities which give flexibility for high volume needs with efficiency and cost reduction.

Shearing

We can shear mild steel and aluminum up to .250″ thick and 10 feet in width.

Metal Finishing

We offer a full service of metal finishing: media blasting, abrasive tumbling, grinding, metal graining/ polishing, painting and galvanizing.

Robotic Welding

Our robotic welding capabilities gives the flexibility for high volume needs with efficiency and cost reduction.

Assembly

From sourcing parts to the building of your product/machine/idea we place quality control as our highest priority when assembling. We offer a variety of pre-assembly options on many of our products which reduces field time and material costs, while also aiding in quicker installation.

Quality Service & Competitive Pricing

Our comprehensive, state of the art manufacturing facility specializes in the fabrication of steel products. We are equipped to produce a broad range of products, from simple detail parts up to complex multi-level assemblies.

We thrive using the simple philosophy of competitive pricing, excellent lead times, professional workmanship and outstanding customer service.

As a major consumer of steel, Valley Fab Corp stocks a large amount of steel and is ready to meet any demand.

We offer full fabrication, machining, and manufacturing capabilities to meet your specific needs. Below are some of our core capabilities, but we are willing to take on other value-added projects as required to support our customers. Please contact us with any questions regarding our capabilities.

Machines

• Amadae Laser Machine

• Titan Burn Table

• Messer Burn Table

• Ocean Avenger Beam Line

• Hydemich M-16A Saw

• Hydem V20 Saw

• CNC Beamline

• Mazak Machine

• Haas VF1 Machine

• Haas TL3 Machine

• Metaform Roll Former

• VT100HML-60-Cts-Saw

• Spartans Iron Worker

• GRD50 Flex Drill Machine

• Acer Drill Brake

• Accurl Press Brake

• Cincinnati Press Brake

• Truck Punch Presses (X3)

• Accurl Shear

• Whitney Press Brake

Machine Capabilities

Laser & Plasma:

Our lasers range in power up to 4000 watts with the capability of cutting mild steel up to .750″ thick, stainless steel up to .500″ and aluminum up to .250″. We have high-definition Plasma capabilities that can process up 2″ thick in addition to torch-cutting.

Press Brake

Our press brake range from 100 to 750 tons and is capable of forming steel parts up to 16 feet wide. We have a wide variety of flexible tooling to accommodate most part configurations.

Welding

At Valley Fab Corp we distinguish ourselves by providing the best welding services available. Our welding department staffs certified welders to AWS D1.1 to ensure consistent quality and reliable welds. In addition, we have robotic welding capabilities which give flexibility for high volume needs with efficiency and cost reduction.

Shearing

We can shear mild steel and aluminum up to .250″ thick and 10 feet in width.

Metal Finishing

We offer a full service of metal finishing: media blasting, abrasive tumbling, grinding, metal graining/ polishing, painting and galvanizing.

Robotic Welding

Our robotic welding capabilities gives the flexibility for high volume needs with efficiency and cost reduction.

Assembly

From sourcing parts to the building of your product/machine/idea we place quality control as our highest priority when assembling. We offer a variety of pre-assembly options on many of our products which reduces field time and material costs, while also aiding in quicker installation.